- Products

Sensors

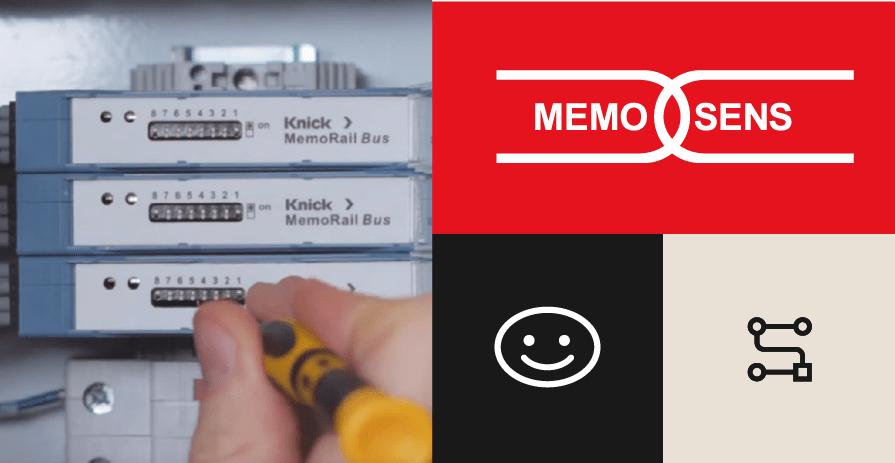

Transmitters & Systems

Sensor Management

Holders & Fittings

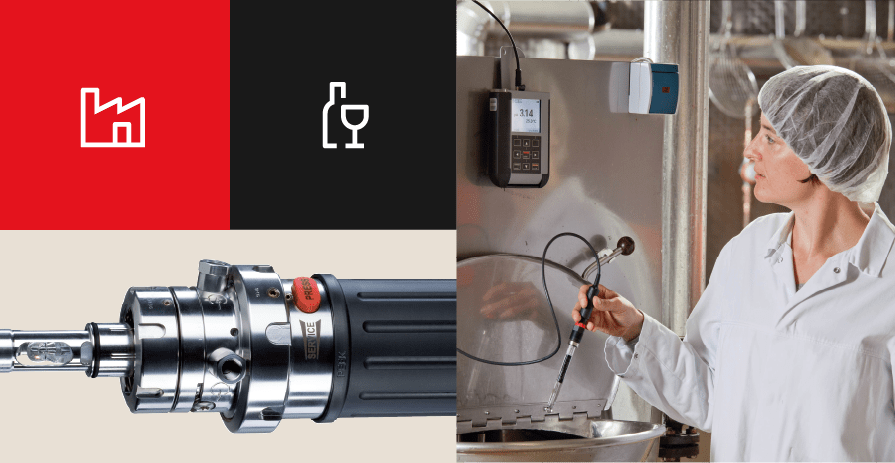

- Industry Solutions

- Service & Support

SUPPORT TOOLS

TRAINING

TECHNICAL SUPPORT

Get assistance with setup, configuration, calibrations, or troubleshooting

- Blog

- Memosens

Get assistance with setup, configuration, calibrations, or troubleshooting

Memosens sensors and automated solutions for pH, ORP, conductivity, and dissolved oxygen measurements

Most end-users spend too much time and money on critical measurements; feeling stuck with problematic equipment. You deserve better. M4 Knick helps you find a simpler solution.

Testimonials

We work with you to find the right solution for each application. See what our great customers have to say.

John Matter / Brewmaster

John Matter / Brewmaster

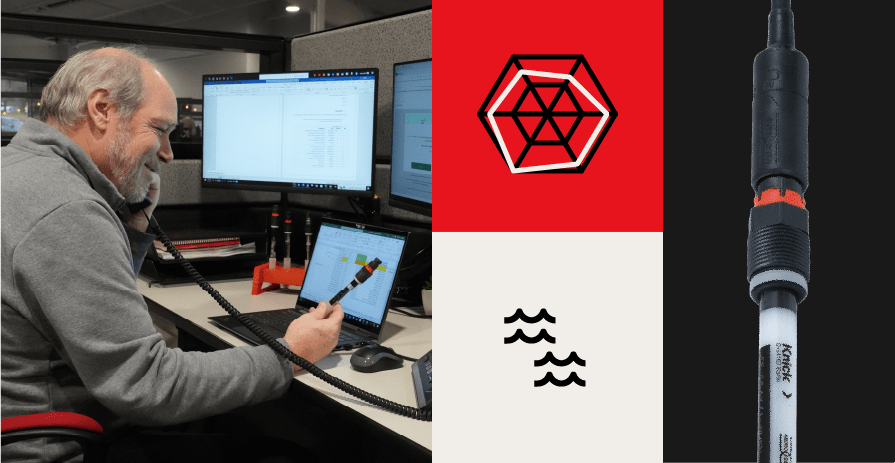

M4 Knick delivers smart liquid analysis technology for manufacturers and municipalities. Our sensor, transmitter, and holder offering work together to form an advanced measurement loop. Components may also be purchased individually.

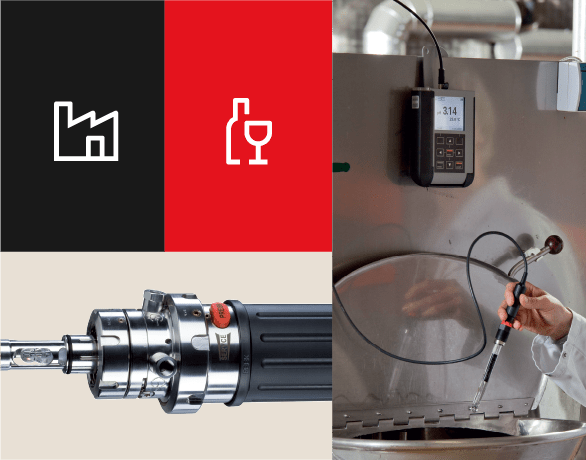

Increase the life of your measuring loop and cut maintenance costs with an all-in-one cleaning and calibration system.

Increase the life of your measuring loop and cut maintenance costs with an all-in-one cleaning and calibration system.

Here’s how M4 Knick can deliver the convenience and confidence you need to keep production moving.

We help you evaluate your measurement loop and apply a new measurement technology that will overcome the challenges you face.

You’ll see how simple it is to monitor, fix, and calibrate sensors. Nearly every customer who sees our equipment in action switches to M4 Knick.

We’ll support you through installation, commissioning, and maintenance. We stand by our products through the entire lifetime of your measurement loop.

Insights for Simplified Measurements