Inductive technology is now commonly found in a wide array of consumer products. It transfers data, charges batteries, or directly powers devices. An innovation that’s so simple, it’s hard to believe the impact can be so significant. Common products include a simple electric toothbrush, a smartphone, and implantable medical devices. The industrial world has begun using inductive technology to improve measurement performance and reduce time spent maintaining equipment in liquid analytics. The debut of the inductive circuit is having a positive impact on the way users interact with liquid analytical products such as pH/ORP, conductivity, and DO sensors. A waterproof, quick disconnect that guarantees you will save time and money. How does it work, and why is so significant?

Inductive Circuit – Theory of Operation

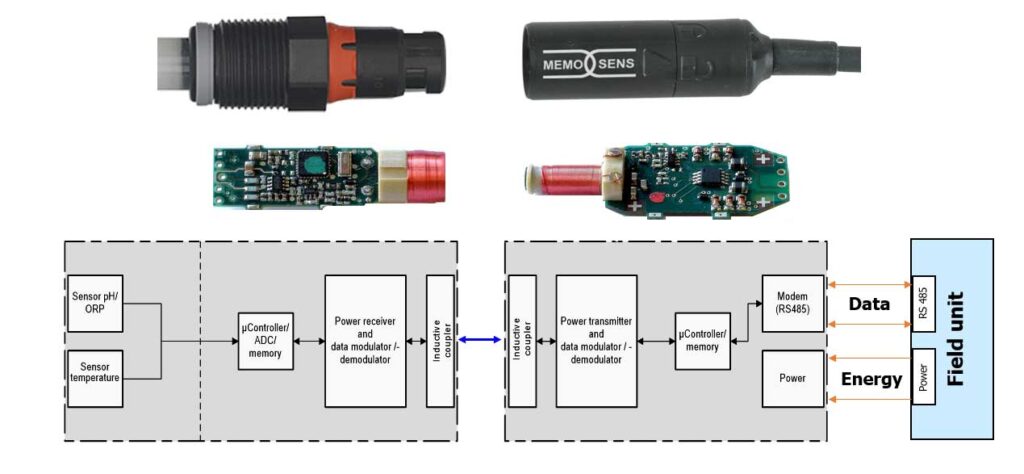

An induction coil creates an alternating electromagnetic field that transfers power and data to a second coil, which converts the field back into an electric current.

Benefits of Inductive Technology for Liquid Analytics

-

Immune to Moisture

Historically, sensor and cable connections have used metal components to transfer power and signal between the sensor and transmitter. Analog and digital sensors with conductive quick-disconnects are susceptible to moisture. The exposure of the metal components to moisture increases the probability of measurement inaccuracy or equipment failure due to corrosion on the contacts inside the connector.

Because induction coils use an electromagnetic field to transfer power and data, metallic contacts are not required. Hermetically sealed coils in the sensor head and cable connection are immune to moisture and even submersible. As a result, this unique capability eliminates measurement inaccuracy and equipment failure.

-

Immune to Electrical Noise and Grounding Issues

Common issues with analog technology are signal leakage, noise from electrical interference, and ground loops. All three of these can create measurement drift and lead to frequent calibration and the perception that a sensor has prematurely failed.

With inductive technology, sensors and transmitters communicate via a digital RS-485 signal as opposed to a voltage change. Replacing the electrical loop eliminates the noise and grounding issues associated with analog technology. In other words, with RS-485 communication, we now have a more reliable measurement, less frequent calibration, and fewer sensor replacements.

-

Offline Calibration

Technicians must calibrate the transmitter, cable, and sensor together for analog measurements. Therefore, the person conducting the maintenance must transport all the tools, spares, and solutions required to clean and calibrate the loop to the point of measurement. Metal sensors and cable connections exposed to the environment can cause faulty calibrations.

Hermetically sealed, inductive sensors have microprocessors embedded in the head. This makes it possible to do true offline calibrations instead of at the point of measurement. Technicians can calibrate in a controlled environment and at a time most convenient for them. The sensor can then be “hot-swapped” in the field, at any time, in any environment.

With the elimination of issues caused by moisture and electrical interference, and the ability to perform calibrations offline, inductive technology is changing the world of online liquid analytics for the better. In short, users now have a more reliable measurement while spending less time in the field maintaining and replacing equipment.