Robust pH Monitoring in Cold Wort using CIP Systems

Wort has to pass through many steps before it can begin fermentation. Wort pH affects clarity, hop bitterness, and the taste profile. The ideal pH of the wort is between 5.0 and 5.5.

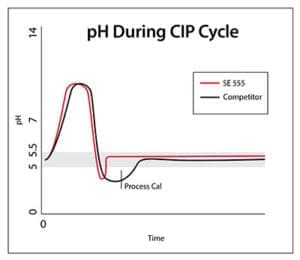

Before the wort leaves the whirlpool and passes through a heat exchanger, a clean-in-place (CIP) cycle ensures there is no contamination from the previous wort transfer. CIP systems automate cleaning and sterilization in the process vessels and piping. Many pH electrodes have a hard time recovering from the extreme temperatures & high pH encountered during the CIP. Therefore, it’s not uncommon for pH sensors to require frequent process calibrations to compensate for the impact of cleaning. In “worst case” scenarios, the operator may need to shut down the cold wort transfer process.

The Solution

The SE555 digital Memosens® pH sensor has been specifically designed to withstand both normal operating conditions of the process and the CIP cycle. The combination of a ceramic diaphragm and Silamid® reference system allows the SE555 to quickly recover and stabilize after CIP. In addition, these two components slow the process from leaching into the sensor and damaging the reference system. Therefore, the SE 555 will require fewer process calibrations and have a longer service life.

Compared to older technologies, Memosens smart digital technology makes calibration and sensor replacement simple. Inside the Memosens electrode is a microprocessor which allows offline calibration and diagnostics using a portable analyzer called the Portavo 907. The Portavo allows technicians to pre-calibrate the sensor and troubleshoot in the shop instead of in the process area. After calibration, the technician can simply carry the SE 555 to the transmitter and “hot-swap” the old sensor with no additional configuration.

In humid environments, sensors using metal connections and coaxial cables are susceptible to corrosion causing drift and sensor failure. The Memosens inductive connection head is completely immune to these conditions. The molded plastic is hermetically sealed and submersible. This means that there is no possibility of corrosion or interference with the transmitted digital signal.

What was this Customer’s Return on Investment?

Reduced downtime: The SE555 pH sensor rapidly recovers and stabilizes from CIP during the cold wort transfer. More responsive pH sensors reduce the number of process calibrations leading to fewer production disruptions.

Reduced maintenance time and costs: The inductive connection removes sensor and cable failures due to corrosion from high moisture environments.

Technicians can take Memosens sensors, calibrated in the shop, directly into the field for installation without any extra steps. When plugged into the transmitter, the sensor automatically shares its calibration data, thus eliminating the need for calibrations in the field.