- Products

Sensors

Transmitters & Systems

Sensor Management

Holders & Fittings

- Industry Solutions

- Service & Support

SUPPORT TOOLS

TRAINING

TECHNICAL SUPPORT

Get assistance with setup, configuration, calibrations, or troubleshooting

- Blog

- Memosens

Get assistance with setup, configuration, calibrations, or troubleshooting

Accurate and reliable liquid analytics are critical to maintaining compliance, ensuring product safety, and optimizing production efficiency in pharmaceutical manufacturing. M4 Knick delivers precise pH, conductivity, and dissolved oxygen measurement solutions designed to meet rigorous regulatory standards and enhance operational effectiveness.

Accurate and reliable measurements are critical to maintaining compliance, ensuring product safety, & optimizing efficiency in pharmaceutical manufacturing. We deliver precise pH, conductivity and dissolved oxygen measurement solutions that meet regulatory standards and enhance operational effectiveness.

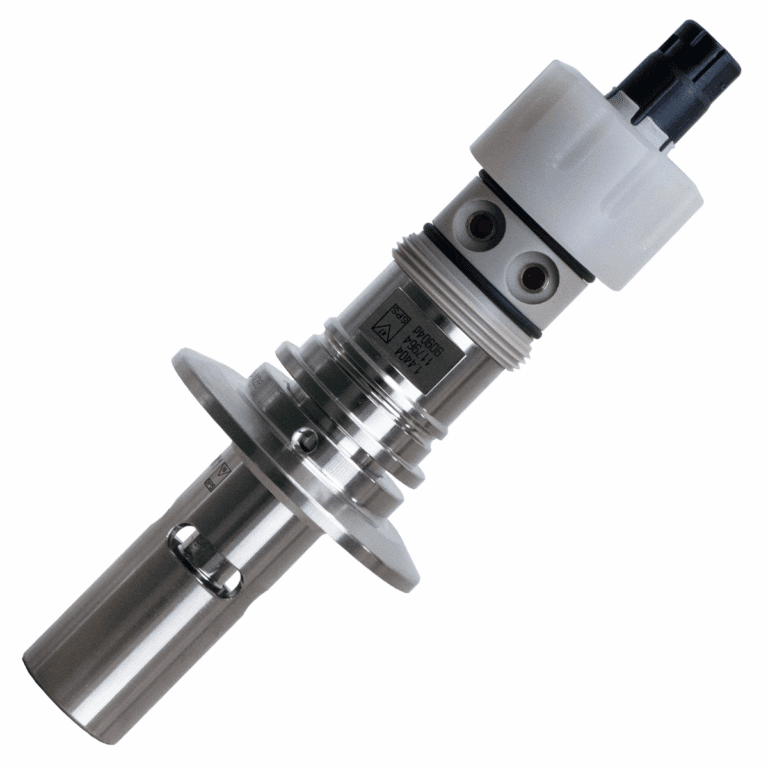

All-Purpose pH Sensor

Designed to withstand extreme pH ranges and CIP/SIP cycles

2-Electrode Conductivity Sensor with CondCheck

Integrated measured value verification in compliance with USP <645>

Low Maintenance Optical Oxygen Sensor

Ideal for reliable measurements in hygienic applications

Modular 4-wire, Multi-parameter Transmitter

Designed for monitoring and controlling pH, conductivity, & oxygen.

Multi-Parameter Transmitter

The most versatile and flexible transmitter on the market for pH, conductivity, & oxygen.

Hygienic Retractable Holder for cCare Systems

Portable Meter with Data Storage, USB, & Printing

Handheld portable meter and calibration tool for pH, conductivity, & oxygen sensors

Automatic Sensor Cleaning and Calibration System

Specially designed to meet calibration and cleaning requirements for the pharma industry

ISFET Memosens pH Sensor

PEEK, glass-free design with CIP/SIP capabilities

Ultrapure Water pH Sensor

Low maintenance pH sensor, ideal for ultrapure water

Hygienic Toroidal Conductivity Sensor

Sensor with smooth, polished finishfor pharmaceutical and SIP applications

High-Resolution Trace Oxygen Sensor

Dissolved oxygen sensor for reliable measurements in hygienic conditions

Hygienic Ingold Static Holder

Fits 120 mm long pH, conductivity, or oxygen sensor with DN 25 Ingold fitting

Static Tri-Clamp Holder

Simple tri-clamp static holder for 120 mm pH, conductivity, or oxygen sensors

Hygienic Retractable Holder with Manual Drive

Retractable holder for 225 mm pH, conductivity, and oxygen sensors in hygienic applications

Portable Meter for Hazardous Areas

Handheld meter and calibration tool for pH, conductivity, or oxygen sensors in Ex-rated areas

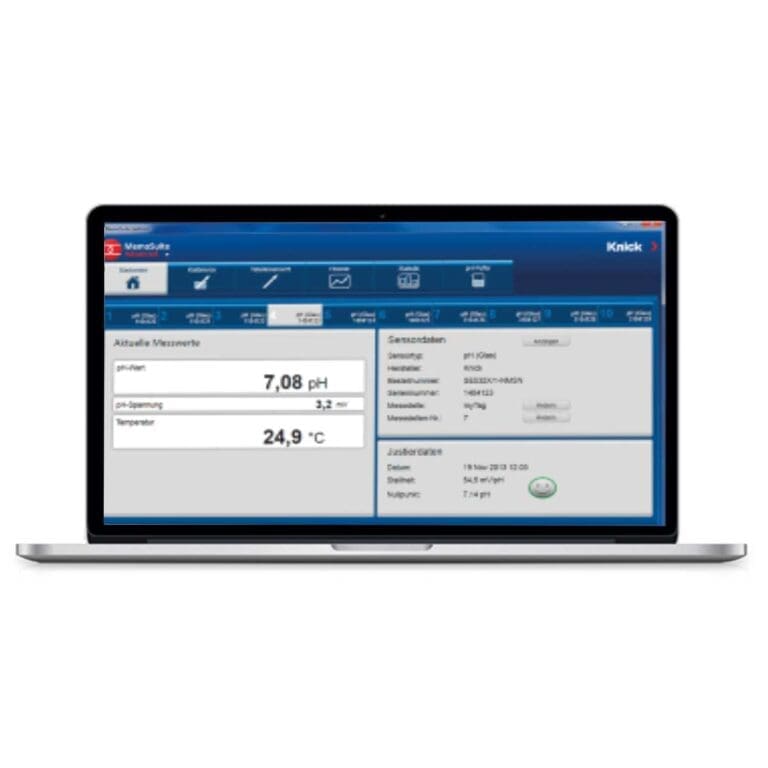

Sensor Management Software

Software for data management and calibrating tool for Memosens® sensors

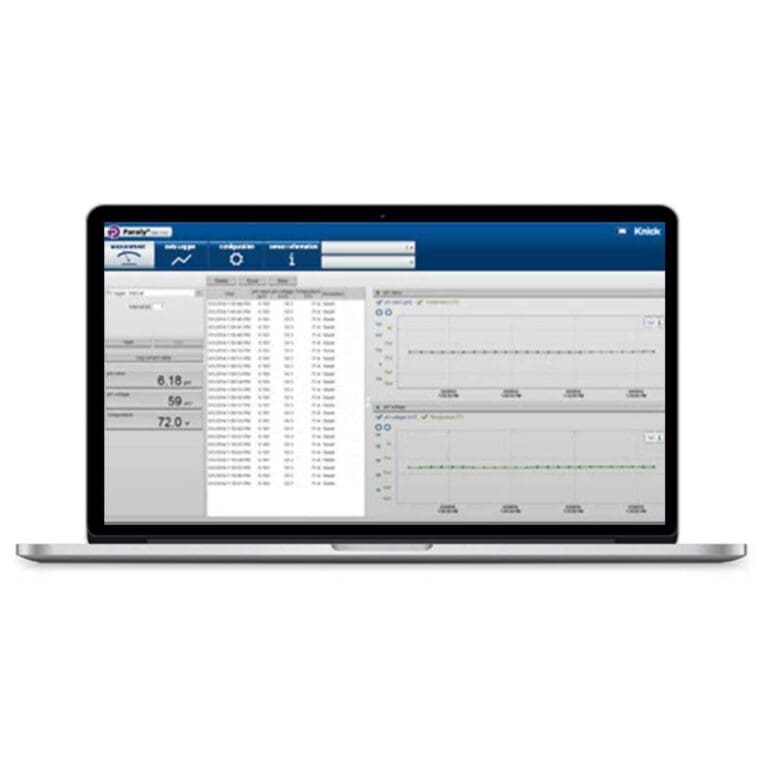

Data Collection Software for Memosens Sensors

Convenient data collection management and configuration of Portavo, portable meters

In pharmaceutical manufacturing, lab and process teams rely on consistent, traceable measurements to ensure product quality and meet compliance standards. Lab verification is often essential for batch release, while process sensors support real-time adjustments.

Memosens technology can also benefit the lab: