Simple Electro-Pneumatic Cleaning System

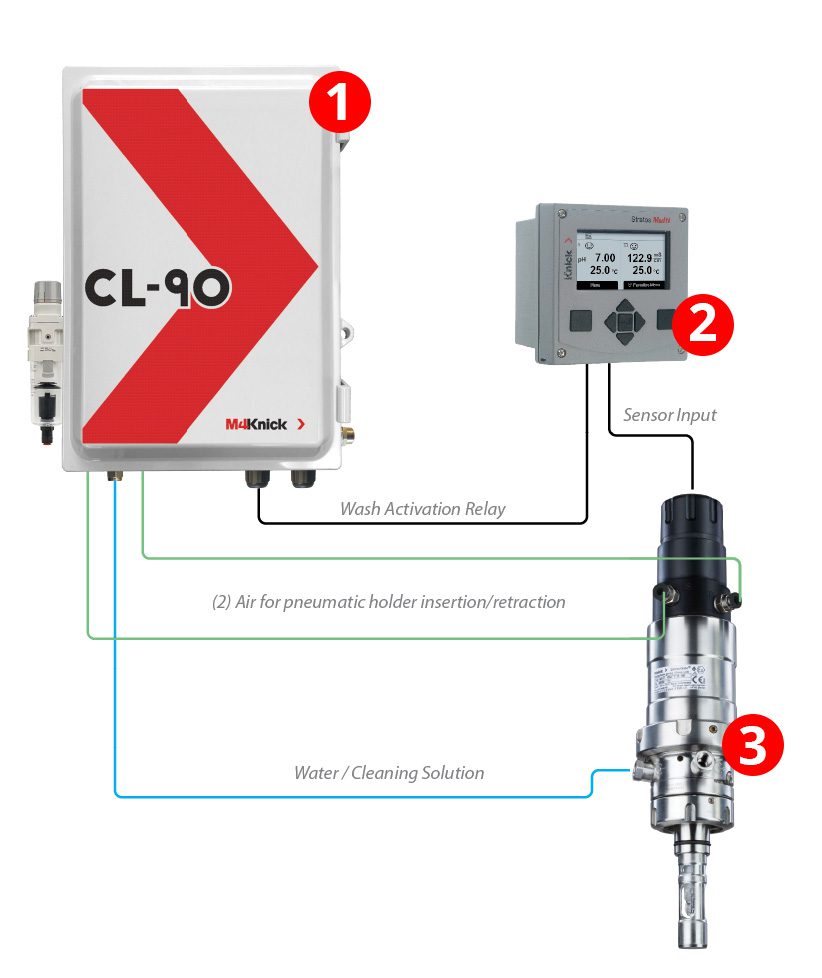

The CL-90 electro-pneumatic cleaning system is a cost-effective tool that helps address pH, ORP, and dissolved oxygen sensor performance issues in processes containing suspended solids. When paired with the Stratos Multi transmitter and Sensogate WA 131 pneumatic retractable holder, the CL-90 provides a compact engineered solution for the automatic retraction, cleaning, and insertion of inline process sensors.

Programming of the Wash Activation Relay in the Stratos Multi allows for a customized cleaning cycle that is best suited for your application. If desired, the CL-90 can be activated remotely by your control system. A manual control lever is also available for an on-site cleaning cycle to be activated on-demand.

QUICK SPECS

Operating Temperature: 41… 113°F (5 … 45 °C)

Dimensions: 10.6” x 10.6” x 6.7” – PET

Consumption kW/h: 20 W

Water Connection: G ¼”

Control air connection: Ø ¼” push button for polyethylene tubing

Protection: IP66 / NEMA 4X

Approximate Weight: 8.8 lbs (4 kg)

Air Consumption: 4 … 7 bar (58 … 101 psi)

Working Voltage: 110 VAC (± 10 %) / 60 Hz

TYPICAL APPLICATIONS

Processes Containing:

- Suspended solids

- Aggressive or hazardous media

Processes Requiring:

- Regular manual cleaning

- Frequent sensor calibrations due to drift

- Numerous sensor replacement due to buildup and wear

CL-90 Cleaning System Anatomy

1. CL-90: Elecro-Pneumatic Control Box

Activated by:

- Programmable wash relay in Stratos Multi

- PLC/DCS

- Manual lever

2. Stratos Multi: 2 -Channel, Multi-Parameter Transmitter

- Integrated wash activation relay

- Backlit LED

- Multi-color sensor/loop health indicator

3. Sensogate 131: Pneumatic Retractable Holder

- Customizable pneumatic retractable holder.

- Materials of construction, insertion depth, and process fitting

- Available for sanitary applications

- Patented “Cyclone” cleaning function