- Products

Sensors

Transmitters & Systems

Sensor Management

Holders & Fittings

- Industry Solutions

- Service & Support

SUPPORT TOOLS

TRAINING

TECHNICAL SUPPORT

Get assistance with setup, configuration, calibrations, or troubleshooting

- Blog

- Memosens

Get assistance with setup, configuration, calibrations, or troubleshooting

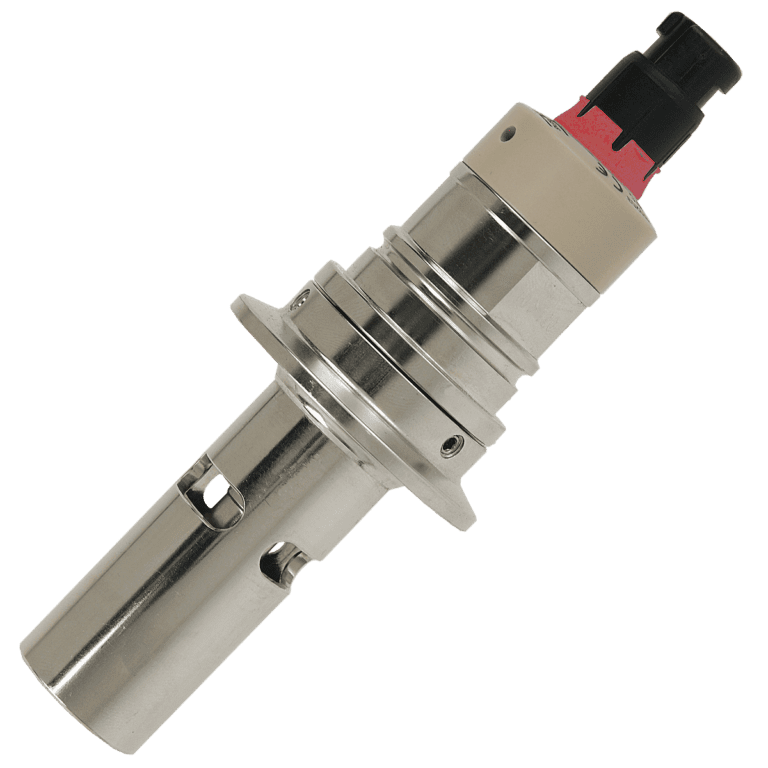

The M4 Knick back pressure relief valve regulates upstream pressure for analytical measurement sensors.

| Wetted parts: | 316 SS and Viton |

| Mounting: | Surface |

| Pressure: | 1.5 bar (21 psig) |

| Temperature: | Up to 167 °F (75 °C) |

| Process Connections: | 1/4″ NPT |

| Dimensions: | 3.0625″ (78 mm) diameter / 3.625″ (92 mm) height |

| Weight: | 2.2 lb (1 kg) |

| Title | Type | |

|---|---|---|

| Sample Conditioning & SWAS Application Data Sheet | Application Data Sheet | DOWNLOAD |

| DOWNLOAD | ||

| BPR Valve Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| BPR Valve Manual | Manual | DOWNLOAD |

| DOWNLOAD | ||

Don’t be limited by your equipment, start using pain-free instrumentation & keep production moving.

| Wetted parts: | 316 SS and Viton |

| Mounting: | Surface |

| Pressure: | 1.5 bar (21 psig) |

| Temperature: | Up to 167 °F (75 °C) |

| Process Connections: | 1/4″ NPT |

| Dimensions: | 3.0625″ (78 mm) diameter / 3.625″ (92 mm) height |

| Weight: | 2.2 lb (1 kg) |

| Title | Type | |

|---|---|---|

| Sample Conditioning & SWAS Application Data Sheet | Application Data Sheet | DOWNLOAD |

| DOWNLOAD | ||

| BPR Valve Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| BPR Valve Manual | Manual | DOWNLOAD |

| DOWNLOAD | ||

Don’t be limited by your equipment, start using pain-free instrumentation & keep production moving.