- Products

Sensors

Transmitters & Systems

Sensor Management

Holders & Fittings

- Industry Solutions

- Service & Support

SUPPORT TOOLS

TRAINING

TECHNICAL SUPPORT

Get assistance with setup, configuration, calibrations, or troubleshooting

- Blog

- Memosens

Get assistance with setup, configuration, calibrations, or troubleshooting

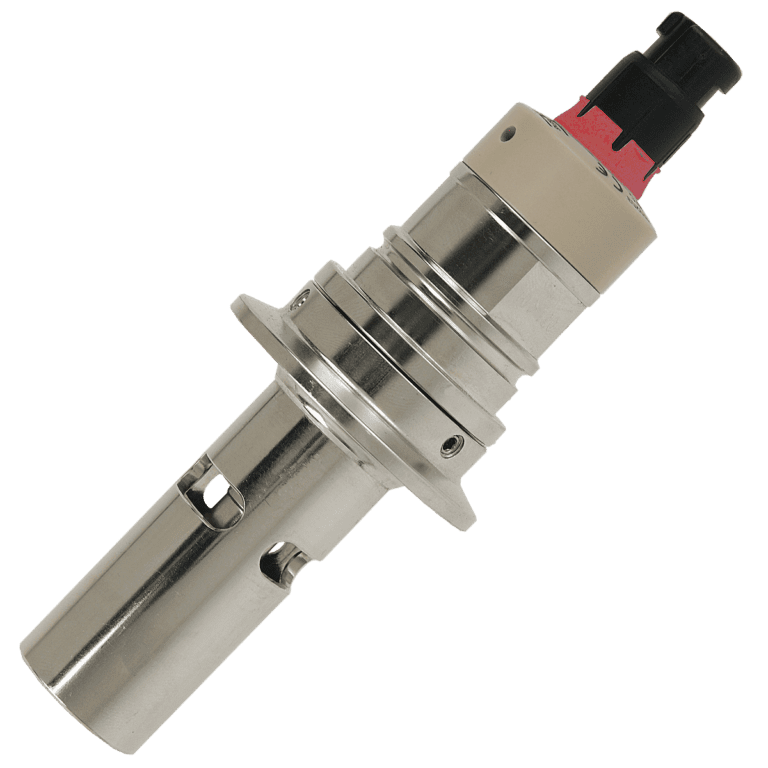

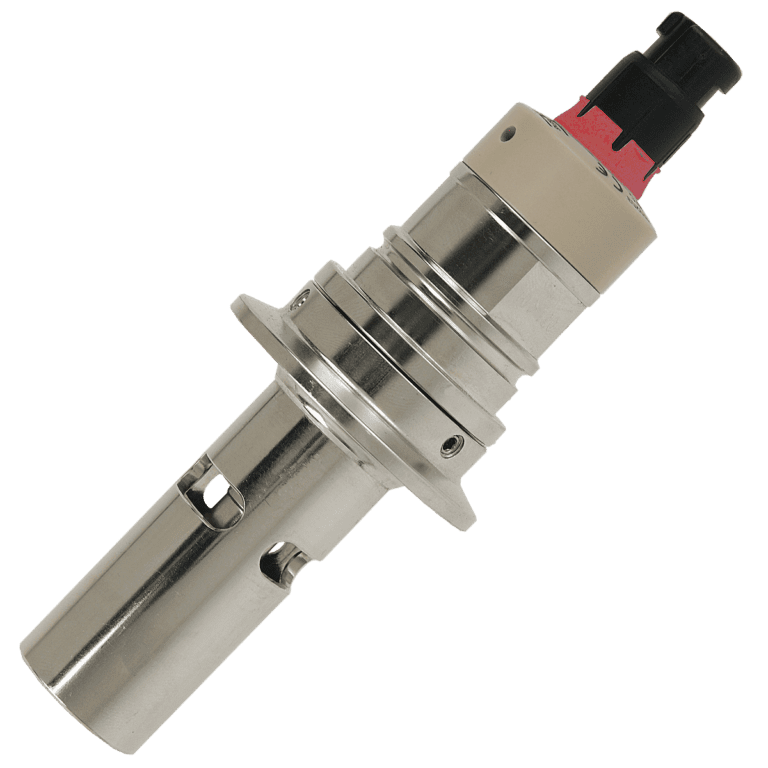

SC sample coolers provide the most cooling efficiency, allowing them to be suitable for most liquid, gas, or steam processes.

| SC-1 | SC-2 | SC-3 | SC-4 | |

| Weight | 11 lbs | 15.4 lbs | 24.25 lbs | 26.46 lbs |

| Tube size | ¼” OD x 0.049″ | ¼” OD x 0.049″ | ⅜” OD x 0.065″ | ⅜” OD x 0.065″ |

| Cooling area | 1.2 ft² | 2.4 ft² | 3.8 ft² | 4.8 ft² |

| Tube temperature | 1004 °F (540 °C) | 1004 °F (540 °C) | 1004 °F (540 °C) | 1004 °F (540 °C) |

| Tube pressure | 3552 psig (245 bar) | 3552 psig (245 bar) | 3118 psig (215 bar) | 3118 psig (215 bar) |

| Shell pressure | 435 psig (30 bar) | 435 psig (30 bar) | 435 psig (30 bar) | 435 psig (30 bar) |

| Tube material | 316SS | 316SS | 316SS | 316SS |

| Shell material | 316SS or 304SS | 316SS or 304SS | 316SS or 304SS | 316SS or 304SS |

| Weight |

| SC-1: 11 lbs SC-2: 15.4 lbs SC-3: 24.25 lbs SC-4: 26.46 lbs |

| Tube size |

| SC-1: ¼” OD x 0.049″ SC-2: ¼” OD x 0.049″ SC-3: ⅜” OD x 0.065″ SC-4: ⅜” OD x 0.065″ |

| Cooling area |

| SC-1: 1.2 ft² SC-2: 2.4 ft² SC-3: 3.8 ft² SC-4: 4.8 ft² |

| Tube temperature |

| SC-1: 1004 °F (540 °C) SC-2: 1004 °F (540 °C) SC-3: 1004 °F (540 °C) SC-4: 1004 °F (540 °C) |

| Tube pressure |

| SC-1: 3552 psig (245 bar) SC-2: 3552 psig (245 bar) SC-3: 3118 psig (215 bar) SC-4: 3118 psig (215 bar) |

| Shell pressure |

| SC-1: 435 psig (30 bar) SC-2: 435 psig (30 bar) SC-3: 435 psig (30 bar) SC-4: 435 psig (30 bar) |

| Tube material |

| SC-1: 316SS SC-2: 316SS SC-3: 316SS SC-4: 316SS |

| Shell material |

| SC-1: 316SS or 304SS SC-2: 316SS or 304SS SC-3: 316SS or 304SS SC-4: 316SS or 304SS |

| Title | Type | |

|---|---|---|

| SC-2 Sample Coolers Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC-2 Sample Cooler Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC-1 Sample Coolers Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC Sample Coolers Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC Sample Coolers Manual | Manual | DOWNLOAD |

| DOWNLOAD | ||

Don’t be limited by your equipment, start using pain-free instrumentation & keep production moving.

| SC-1 | SC-2 | SC-3 | SC-4 | |

| Weight | 11 lbs | 15.4 lbs | 24.25 lbs | 26.46 lbs |

| Tube size | ¼” OD x 0.049″ | ¼” OD x 0.049″ | ⅜” OD x 0.065″ | ⅜” OD x 0.065″ |

| Cooling area | 1.2 ft² | 2.4 ft² | 3.8 ft² | 4.8 ft² |

| Tube temperature | 1004 °F (540 °C) | 1004 °F (540 °C) | 1004 °F (540 °C) | 1004 °F (540 °C) |

| Tube pressure | 3552 psig (245 bar) | 3552 psig (245 bar) | 3118 psig (215 bar) | 3118 psig (215 bar) |

| Shell pressure | 435 psig (30 bar) | 435 psig (30 bar) | 435 psig (30 bar) | 435 psig (30 bar) |

| Tube material | 316SS | 316SS | 316SS | 316SS |

| Shell material | 316SS or 304SS | 316SS or 304SS | 316SS or 304SS | 316SS or 304SS |

| Weight |

| SC-1: 11 lbs SC-2: 15.4 lbs SC-3: 24.25 lbs SC-4: 26.46 lbs |

| Tube size |

| SC-1: ¼” OD x 0.049″ SC-2: ¼” OD x 0.049″ SC-3: ⅜” OD x 0.065″ SC-4: ⅜” OD x 0.065″ |

| Cooling area |

| SC-1: 1.2 ft² SC-2: 2.4 ft² SC-3: 3.8 ft² SC-4: 4.8 ft² |

| Tube temperature |

| SC-1: 1004 °F (540 °C) SC-2: 1004 °F (540 °C) SC-3: 1004 °F (540 °C) SC-4: 1004 °F (540 °C) |

| Tube pressure |

| SC-1: 3552 psig (245 bar) SC-2: 3552 psig (245 bar) SC-3: 3118 psig (215 bar) SC-4: 3118 psig (215 bar) |

| Shell pressure |

| SC-1: 435 psig (30 bar) SC-2: 435 psig (30 bar) SC-3: 435 psig (30 bar) SC-4: 435 psig (30 bar) |

| Tube material |

| SC-1: 316SS SC-2: 316SS SC-3: 316SS SC-4: 316SS |

| Shell material |

| SC-1: 316SS or 304SS SC-2: 316SS or 304SS SC-3: 316SS or 304SS SC-4: 316SS or 304SS |

| Title | Type | |

|---|---|---|

| SC-2 Sample Coolers Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC-2 Sample Cooler Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC-1 Sample Coolers Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC Sample Coolers Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| SC Sample Coolers Manual | Manual | DOWNLOAD |

| DOWNLOAD | ||

Don’t be limited by your equipment, start using pain-free instrumentation & keep production moving.