- Products

Sensors

Transmitters & Systems

Sensor Management

Holders & Fittings

- Industry Solutions

- Service & Support

SUPPORT TOOLS

TRAINING

TECHNICAL SUPPORT

Get assistance with setup, configuration, calibrations, or troubleshooting

- Blog

- Memosens

Get assistance with setup, configuration, calibrations, or troubleshooting

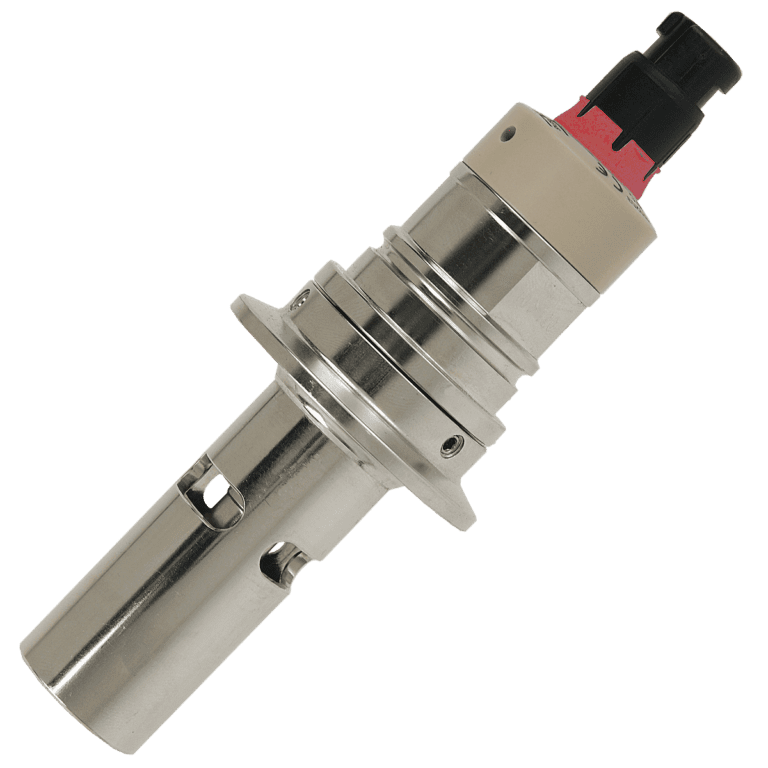

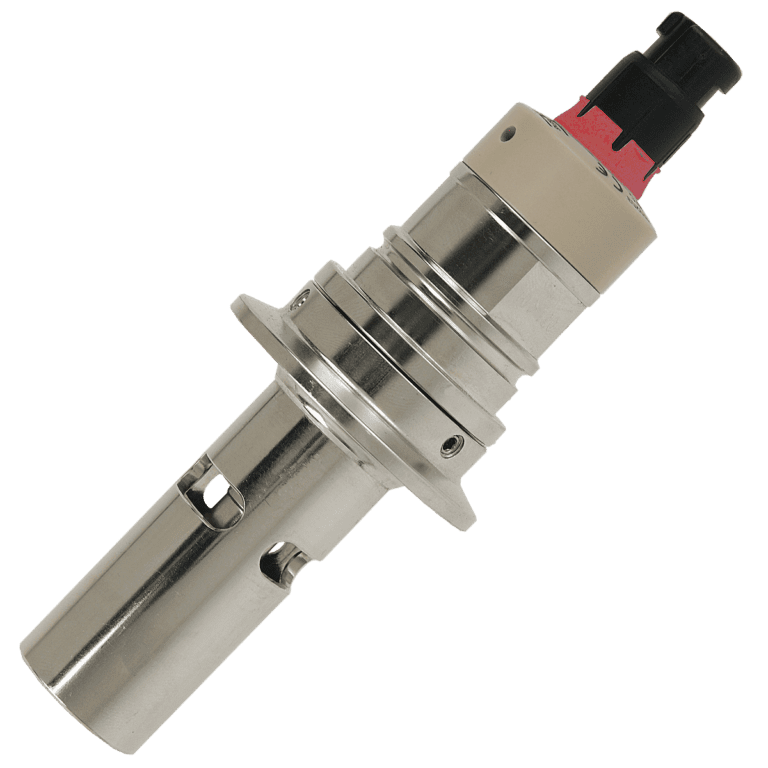

The TVS valve is a thermal shut-off valve that ensures that process fluids remain below the temperature threshold of an analyzer.

| Weight | 2.6 lbs |

| Pressure | 2900 psig (200 bar) |

| Temperature | 356 °F (180 °C) |

| Set point | 120 °F (49 °C) |

| Materials | Stainless steel 316 L |

| Connection | ¼" NPT(f) |

| Weight |

| 2.6 lbs |

| Pressure |

| 2900 psig (200 bar) |

| Temperature |

| 356 °F (180 °C) |

| Set point |

| 120 °F (49 °C) |

| Materials |

| Stainless steel 316 L |

| Connection |

| ¼" NPT(f) |

| Materials: | Stainless Steel 316 L |

| Mounting: | Surface |

| Max Pressure: | 200 bar (2900 psi) |

| Max Temperature: | 356 °F (180 °C) |

| Closing Point: | 120 °F (49 °C) |

| Process Connections: | 1/4″ NPT |

| Weight: | 2.6 lb (1.2 kg) |

| Switch (Optional): | Type: SPDT Protection: IP 67 Operating current: 6 A Operating voltage: 30 Vdc Ambient operating temp: 14–176 °F (-10–80 °C) Ambient operating humidity: 35–95% RH |

| Title | Type | |

|---|---|---|

| Sample Conditioning & SWAS Application Data Sheet | Application Data Sheet | DOWNLOAD |

| DOWNLOAD | ||

| TVS Valve Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| TVS Valve Manual | Manual | DOWNLOAD |

| DOWNLOAD | ||

Don’t be limited by your equipment, start using pain-free instrumentation & keep production moving.

| Weight | 2.6 lbs |

| Pressure | 2900 psig (200 bar) |

| Temperature | 356 °F (180 °C) |

| Set point | 120 °F (49 °C) |

| Materials | Stainless steel 316 L |

| Connection | ¼" NPT(f) |

| Weight |

| 2.6 lbs |

| Pressure |

| 2900 psig (200 bar) |

| Temperature |

| 356 °F (180 °C) |

| Set point |

| 120 °F (49 °C) |

| Materials |

| Stainless steel 316 L |

| Connection |

| ¼" NPT(f) |

| Materials: | Stainless Steel 316 L |

| Mounting: | Surface |

| Max Pressure: | 200 bar (2900 psi) |

| Max Temperature: | 356 °F (180 °C) |

| Closing Point: | 120 °F (49 °C) |

| Process Connections: | 1/4″ NPT |

| Weight: | 2.6 lb (1.2 kg) |

| Switch (Optional): | Type: SPDT Protection: IP 67 Operating current: 6 A Operating voltage: 30 Vdc Ambient operating temp: 14–176 °F (-10–80 °C) Ambient operating humidity: 35–95% RH |

| Title | Type | |

|---|---|---|

| Sample Conditioning & SWAS Application Data Sheet | Application Data Sheet | DOWNLOAD |

| DOWNLOAD | ||

| TVS Valve Spec Sheet | Technical Specifications | DOWNLOAD |

| DOWNLOAD | ||

| TVS Valve Manual | Manual | DOWNLOAD |

| DOWNLOAD | ||

Don’t be limited by your equipment, start using pain-free instrumentation & keep production moving.